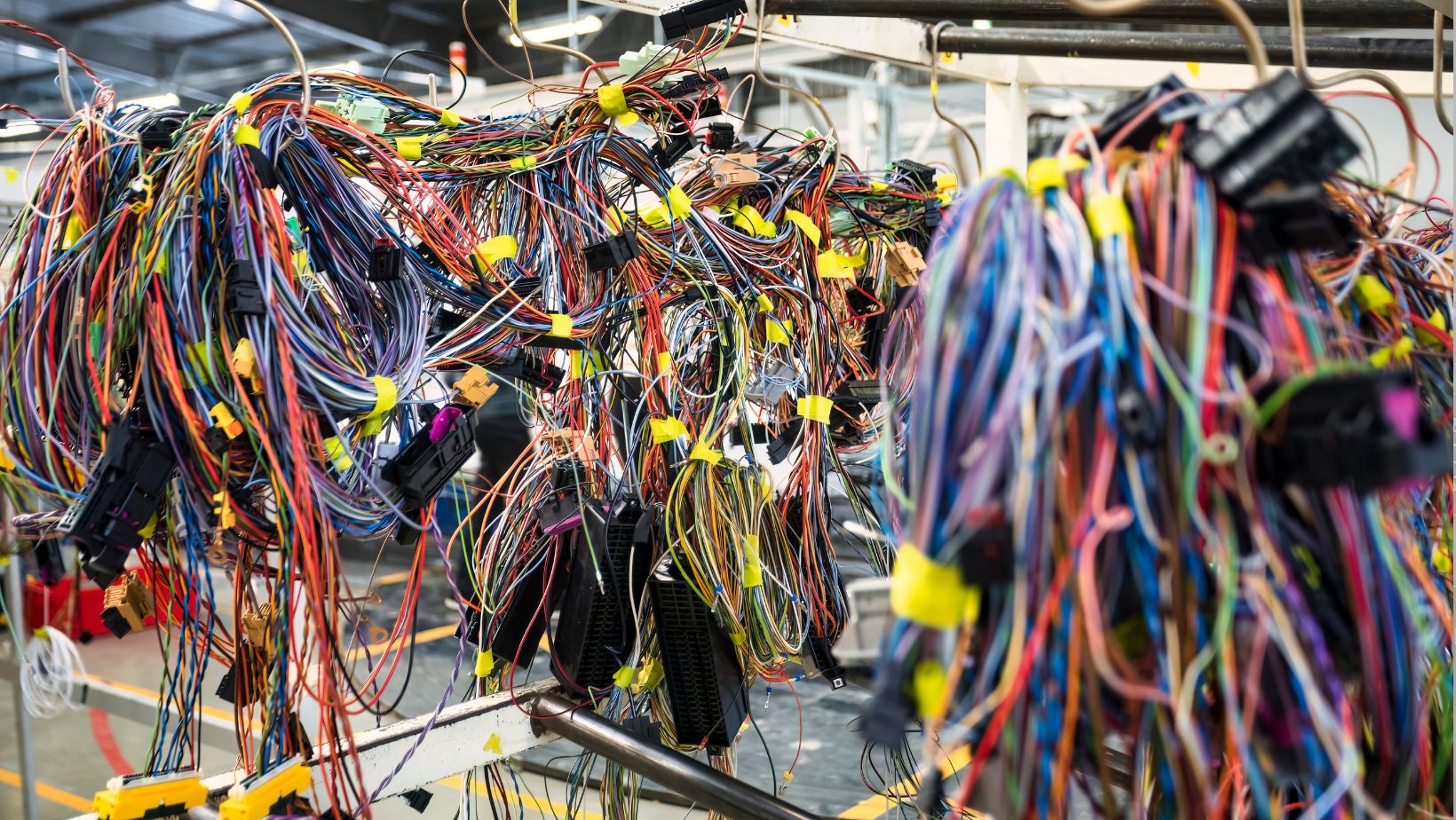

Diving into the world of wiring harness manufacturing can feel like stepping into a complex labyrinth. But fear not! This article is designed to be your guiding light, unraveling the intricacies of this essential component in our technologically driven world.

Wiring harnesses, the unsung heroes of our electrical systems, are more than meets the eye. They’re the lifelines that keep our favorite gadgets humming and our vehicles running smoothly. Understanding their manufacturing process not only demystifies their function but also highlights their importance in our daily lives.

Wiring Harness Manufacturing Understanding:

Diving deeper into the world of wiring harness manufacturing, it becomes evident that precision, and expertise play a pivotal role. Each wiring harness, much like a maze, is specifically designed to transmit energy and signals seamlessly. This transmission relies heavily on the intricate construction of the harness, affirming its necessity in our increasingly digital world.

A detailed look reveals two crucial phases – designing, and production. Designing focuses on creating a blueprint for each unique wiring harness. The intricacies required in this phase demand the skill of seasoned professionals. Following suit, the production phase embeds life into these designs, translating them into a functional apparatus. High-level competency is an absolute requirement during production as it involves critical tasks such as wire cutting, striping, and crimping.

Exploring the area of the material used, substantial consideration goes into choosing the right components. It is in this stage where the functionalities of wire types, connectors, terminals, and other aspects are reviewed thoroughly.

Lastly, testing is a critical factor, without which the reliability of the manufactured wiring harness can’t be guaranteed. Typically, electrical tests are conducted to verify continuity and to ensure there are no short circuits.

What does Your Contract Manufacturer (CM) Need for the Wiring Harness Manufacturing?

As an industry frontrunner, Cloom exemplifies the contract manufacturer’s role in prevalent wiring harness production. Critical factors determine successful contract manufacturing in this field.

Reduction of manufacturing time, identification of bottlenecks, and efficient resource allocation pinpoint the necessities for your CM.

1. Detailed Specifications

The creation of a useful wiring harness commences with thorough specifications. These include dimensions of the harness, types and sizes of wires, connector types, and pinouts.

2. Target Use and Environment

The CM requires detailed information on the intended application and environment. This knowledge is key in determining material selection, and it dictates aspects such as insulation type, wire gauge, and durability parameters.

3. Bill of Materials (BOM)

The BOM provides crucial information for the CM, including the list of components, their quantities, and the specifications necessary to build the wiring harness. The CM uses this for material sourcing and to estimate the final cost of production.

4. Regulatory Guidelines

To ensure safe operation and legal compliance, knowledge of regulatory guidelines such as RoHS and UL standards is mandatory. In response, a CM like Cloom ensures adherence to these rules, ensuring product quality and safety.

5. Design Blueprint

A comprehensive design schematic proves crucial for successful wiring harness production. The blueprint provides detailed routing, join points, and terminal connections, ensuring the CM can create an effective harness.

Wiring Harness Manufacturing Process:

Harness manufacturing begins with a detailed blueprint. This map outlines every wire, connector, protocol, and even color coding. Precision excels in companies like Cloom that strictly adhere to these blueprints. This adherence is crucial in ensuring that the final product is both efficient and of high quality.

There’s an initial step of cutting and stripping the wires. This process involves cutting wires to the right lengths, as specified in the blueprint, then stripping their ends to prepare for the application of connectors. Machines, both automated and manual, play a key role in the cutting and stripping process, depending on the complexity and volume of the task.

Connectors get applied next. They’re crimped onto the stripped wire ends, serving as interfaces for transmitting electrical signals and currents. Equipment like crimping pliers, ratcheting crimpers, or even automated crimping machines are employed for this purpose, again under context of task enormity.

Wiring Harness Manufacturing Challenges:

Despite the meticulous process followed by companies, like Cloom, to manufacture high-quality and efficient wiring harnesses, multiple challenges persist in such technical production. These challenges mostly involve managing the complexities of design, maintaining regulatory compliance, and controlling production costs.

For instance, harness design complexities ensue when accommodating for a wide array of wire types, sizes, and connector models. Increasing the variability in a single harness design raises manufacturing complexities, thus demanding additional resources and time for production.

Secondly, meeting industry standards and regulatory guidelines consistently can pose a formidable challenge. Stringent testing for electrical safety, durability, and performance is compulsory to verify wiring harnesses’ compliance with established norms. However, with the evolving nature of these regulations, staying updated and consistently conforming to all these guidelines becomes challenging.

Additionally, production cost control represents another major challenge. From sourcing high-quality raw materials to maintaining efficient production lines, each contributes to the final cost reality. In cases where specialized tools or human expertise is necessary for assembly or testing—such as the technical precision exhibited by Cloom—it substantially influences overall production costs.

Conclusion

Wiring harness manufacturing is a testament to precision, expertise, and resilience. Companies like Cloom have set the bar high, showcasing technical precision and strict adherence to industrial standards. They’ve navigated the labyrinth of design complexities and regulatory compliance, demonstrating a commitment to quality. Despite the hurdles of controlling production costs and ensuring scalability, these industry leaders have continued to innovate. Their persistence has led to the creation of reliable and efficient wiring harnesses, proving that excellence in this field is achievable. It’s clear that with dedication and technical know-how, these challenges can be overcome, paving the way for the future of wiring harness manufacturing.

More Stories

The Technology Behind Virtual Receptionist Services

Crypto And Cards: The Fusion Of Blockchain And Betting

Tool Overload: Why Less Software Sometimes Means More Progress