In the labyrinth of modern technology, semiconductor supply chains form the intricate arteries vital for the functioning of numerous industries. These complex networks, often veiled in mystery to the layperson, wield significant influence over global markets. Understanding their dynamics, from fabrication to distribution, is paramount in navigating the currents of the tech economy.

The Genesis of Semiconductors

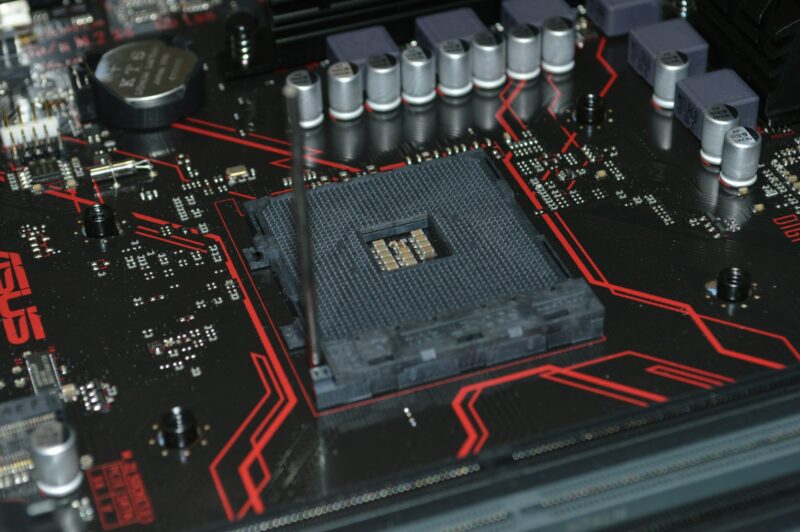

Semiconductors, the backbone of modern electronics, are crafted from materials with properties between those of conductors and insulators. Silicon, germanium and gallium arsenide are among the primary elements utilized by semiconductor companies in the US for manufacturing. The process begins in fabrication facilities known as fabs, where intricate patterning and doping techniques are employed to create semiconductor wafers. These wafers undergo further processing to create intricate electronic components like transistors and diodes.

Fabrication Facilities: The Birthplace of Innovation

Fabs are the cradle of innovation in the semiconductor industry. These highly specialized facilities house the machinery and expertise necessary for the intricate process of semiconductor fabrication. Cutting-edge technologies such as photolithography and ion implantation are employed to etch minuscule circuitry onto silicon wafers, laying the groundwork for a myriad of electronic devices. Each advancement in fabrication techniques paves the way for more powerful and energy-efficient semiconductor devices.

Supply Chain Dynamics

The semiconductor supply chain is a multifaceted ecosystem spanning continents and involving numerous stakeholders. Raw materials sourced from various regions are processed in fabrication facilities, after which the manufactured chips are subjected to rigorous testing. Following this, they are assembled into final products or integrated into larger electronic systems. This intricate dance of supply and demand requires meticulous coordination to confirm the timely delivery of high-quality components to meet the ever-growing global demand for electronics.

Global Interconnectivity

Semiconductor supply chains epitomize globalization, with production facilities dispersed across the globe. Asian countries, particularly Taiwan, South Korea, and China, dominate semiconductor manufacturing, boasting state-of-the-art fabs operated by industry giants like TSMC and Samsung.

Techno-Economic Influence

The techno-economic influence of semiconductor supply chains extends far beyond the realm of technology. These intricate networks wield considerable power over global markets, influencing everything from consumer electronics to national security. The scarcity or abundance of semiconductor components can disrupt entire industries, as witnessed during the recent semiconductor shortage that reverberated through the automotive and consumer electronics sectors. Governments and industry stakeholders are increasingly recognizing the strategic importance of semiconductor manufacturing and are investing in initiatives to bolster domestic production capacities.

Navigating Supply Chain Disruptions

Supply chain disruptions, whether due to geopolitical tensions, natural disasters, or pandemics, underscore the fragility of global semiconductor ecosystems. The recent COVID-19 pandemic laid bare the vulnerabilities inherent in these supply chains, prompting a reevaluation of sourcing strategies and investment in domestic semiconductor manufacturing capabilities. Enhanced collaboration, transparency, and resilience planning are essential for mitigating the impact of future disruptions and achieving stability of semiconductor supply chains.

Geopolitical Implications

Semiconductors have emerged as a geopolitical flashpoint, with nations vying for technological supremacy and strategic autonomy. The United States, in particular, has ramped up efforts to bolster domestic semiconductor production, viewing it as critical to both economic competitiveness and national security. China, too, has embarked on an ambitious quest for semiconductor self-sufficiency, investing heavily in homegrown chip technologies. This geopolitical competition underscores the pivotal role of semiconductors in shaping global power dynamics and underscores the need for strategic foresight and international cooperation.

Future Prospects

The future of semiconductor supply chains is fraught with both promise and peril. Advancements in artificial intelligence, the Internet of Things (IoT), and 5G technology herald unprecedented opportunities for semiconductor manufacturers.

Conclusion

Semiconductor supply chains represent the lifeblood of the modern technological ecosystem, underpinning the functionality of a vast array of electronic devices. Understanding the intricacies of these supply chains is essential for stakeholders across industries, from policymakers crafting economic strategies to consumers navigating the ever-evolving landscape of consumer electronics. Demystifying semiconductor supply chains unveils the intricate dance of technology and economics shaping the global marketplace, illuminating both the opportunities and challenges that lie ahead.

More Stories

Windows VPS vs Linux VPS: Which One Should You Choose?

How to Track Your Fitness Goals as a Student: 5 Essential Apps

What Kind of Programmers Do Companies Want to Hire in 2025