AC servo motors are a great choice for a variety of different applications when it comes to assembly lines or automation processes. They utilize alternating current and can offer highly accurate positioning and speed control, which is useful in many different situations. Knowing more about what this important motor type does can help you shop the smart way for AC motors when you need to upgrade or replace your existing machine components.

Control Techniques parts are a great choice when it comes to buying high-quality AC servo motors for your business. Control Techniques stands behind their products with warranties, and they offer superior customer service as well. If you have been looking for the top AC servo companies out there, Control Techniques should be at the very top of your list for suppliers.

What Are AC Servo Motors?

AC servo motors are electricity motors that are powered by AC (alternating) current. The precision of these motors is controlled perfectly through a feedback mechanism, such as an encoder. This kind of motor makes certain that the positioning and speed control of systems connected to this kind of motor is perfect.

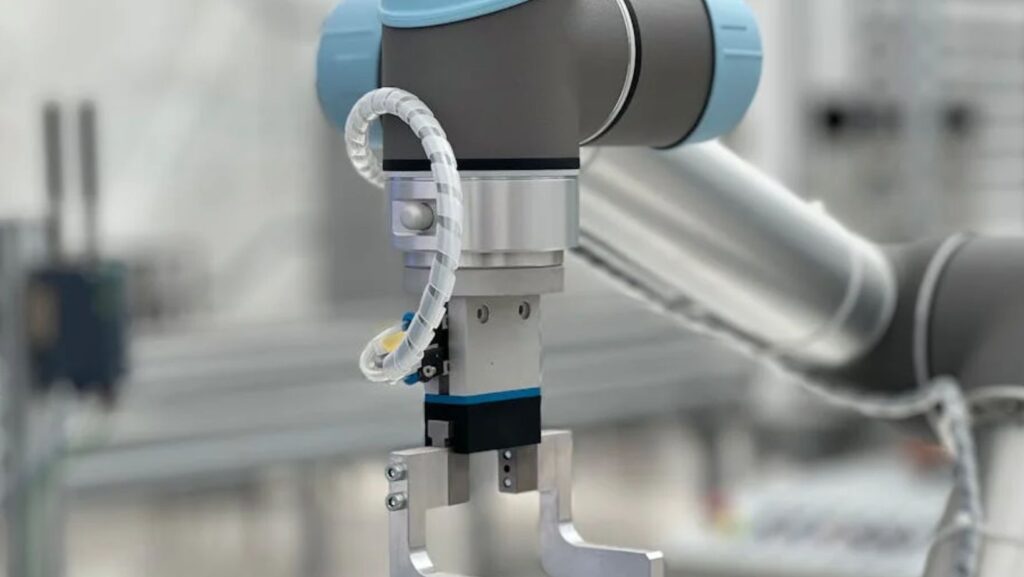

AC servo motors are commonly used in robotics, CNC machines, and industrial automation. They are highly durable and can be counted upon to ensure that production line operations are handled correctly and without any wasted time or effort. These kinds of motors also contribute to cost-savings due to efficiency and improve safety for those who operate the assembly line itself.

DC servo motors operate on direct current which does allow for precision when it comes to speed and position, but which can limit added benefits like the feedback controls that are offered when you select an AC servo motor for your assembly line arrangements.

Benefits of AC Servo Motors

There are many reasons why AC servo motors are highly beneficial for use in industrial settings. They offer closed-loop control, and they are highly accurate. This is due to the closed-loop system that is utilized to ensure that the motor is always getting feedback on its position. The servo motor will then adjust on the fly to maintain the precise control required to handle operational and automation tasks.

These motors can also be used at a wide range of speeds without sacrificing the precision of their actions and operation. This cannot be said for many other kinds of motors, which is why AC servo motors stand out head and shoulders above the crowd for all kinds of automation and industrial work processes.

There are a few cons of these motors, and you should be aware of them when shopping for quality AC servo motors. This kind of equipment will cost more than DC equivalents. You should also be prepared for AC servo motors to be more complex due to their design, which might require that your staff gets updated training in the use and maintenance of these devices before you upgrade or replace existing systems.

Types of AC Servo Motors

There are various styles of AC servo motors that you can pick from. You might need to use a variety of different styles as you are creating solutions for your business. AC servo motors can also be designed to be synchronous with the speed of the current, which offers superior consistency and results in manufacturing and assembly applications. Timing is often critical in assembly line processes, which means that synchronous motor operation is typically key, no matter what kind of other features your motor of choice offers.

Asynchronous motors also exist, and can be used where simpler motor designs and less speed control are required. You might use motors of both types in your assembly processes and it is important to understand that both of these kinds of motors serve different functions and purposes in assembly line environments.

1. Rotary Servo Motor

A rotary servo motor converts electrical energy into rotational motion. There is a rotor section of this kind of motor that rotates and a stator segment that is used to support and contain the rotation of the other half of the device. This kind of mechanism is used with a coupling, a ball screw, or even a cam or pulley to control an object under load and move it.

2. Direct Drive Motor

Direct drive motors are the most commonly used kind of AC motors in manufacturing, and they are used to move items or output torque. There is no backlash or loss of mechanical efficiency with these kinds of drive motors, which is why they are so commonly selected for manufacturing systems.

3. Linear Slider or Linear Motor

These kinds of motors are used to control objects directly. They can move the object in a lateral or straight line through the use of stationary and non-stationary components. The moving parts are called movers and the stationary parts are called stators.

The linear motor is also typically combined with a guide that supports the drive, which is called the linear slider.

to/woman-wearing-pair-of-teal-rubber-gloves-standing-near-white-barrel-1267347/

AC Servo Motors Serve Critical Purposes in Assembly Lines and Automation

If you operate a business that uses assembly line processes and solutions, you are going to need to use AC servo motors in at least some parts of your assembly line processes. It is key to shop for high-quality components for your business, which is why Control Techniques is a great choice for your AC servo motor supplier.

Always be sure that you understand the use and function of the components that you are buying for your business. Being an informed business owner can help you to save money, buy the right products and solutions for your business, and save time and stress by preventing breakdowns and other kinds of manufacturing setbacks. Standing out from the crowd in your market niche often comes down to being able to provide a reliable and consistent experience for your customers. Investing in your daily business operations is a great way to ensure that you will meet this goal each and every day.

More Stories

PDF to Presentation: Automating Document Analysis with AI

Connecting Across Cultures: The Journey with Single Ukrainian Brides

Essential Features Your Online Store Needs from Its Hosting